UV Printing

UV-printing on any surface!

The peculiarity and uniqueness of this type of UV-printing is the use of special UV curable inks. Inks applied to the material by inkjet printing form a film, which is afterwards firmly fixed on the base, so that printing ink does not penetrate the structure. Advantages and features of UV printing: the ability to print in white, production of both large and small runs.

Ultraviolet printing is one of the modern technologies that allows you to apply any high quality image on any type of surface, such as:

- glass

- wood;

- plastic;

- acrylic;

- metal and many other rolled materials.

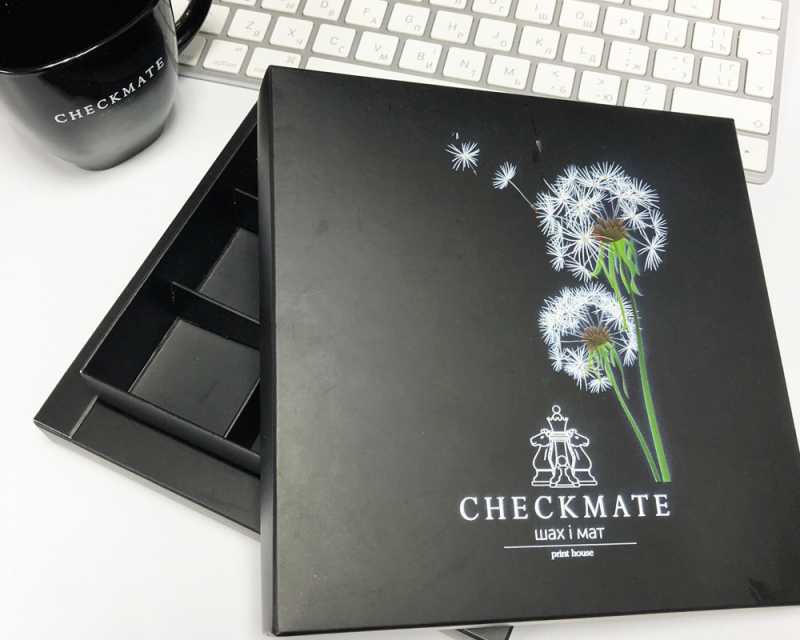

Printing on souvenirs:

- pens;

- lighters;

- flash drives;

- trinkets;

- photo frames and many others.

Production of plates, numbers, badges made of plastic and metal with a full-color image, printing on glass and ceramics, sealing of textured materials, printing on uneven surfaces with a height difference of up to 1 mm without loss of quality, therefore saving time and money.

Thus distinguishes UV-printing technology from traditional methods of applying images, such as silk screen printing and pad printing. Reducing the production cycle time - UV inks dry instantly! - and the lack of preparatory work makes UV-printing technology indispensable for urgent work on applying the image. The height of objects can reach 110 mm, the maximum print size is 610 mm x 900 mm.

The cost of an order always depends on the circulation.

For more information, as well as for an accurate calculation, please contact our consultant.